Solutions & Advantages

In recent years, difficulties in hiring warehouse staff and low operational efficiency have become major challenges. Tailift offers the perfect solution—comprehensive one-stop services for factory automation planning and implementation—to help reduce labor dependence and boost warehouse efficiency. Logistics centers and manufacturing plants often require large numbers of personnel for repetitive and heavy tasks. When labor shortages prevent efficiency improvements, the introduction of automation equipment becomes your best choice.

Tailift provides end-to-end solutions based on your warehouse layout, pallet type, sorting methods, inbound/outbound processes, and inventory workflows. From hardware planning and execution to software integration, we deliver customized upgrade solutions tailored to your factory’s needs—whether it’s semi-automation, full automation, or unmanned operations—to solve all your challenges.

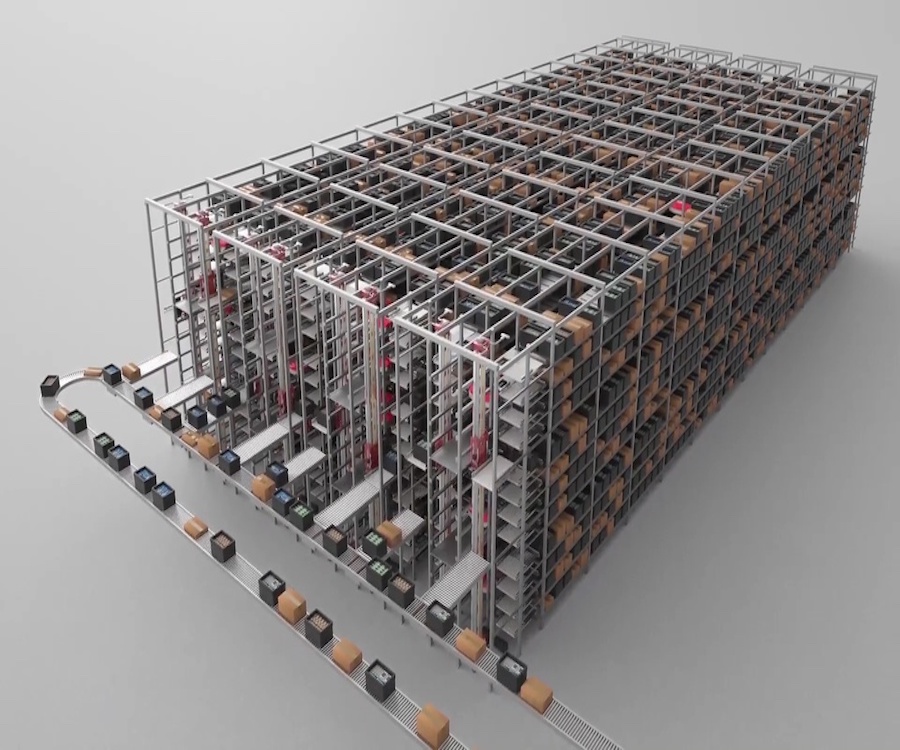

Tailift offers comprehensive logistics and storage solutions suitable for all types of warehouses and production environments. Our automation systems are designed to improve efficiency, reduce costs, and ensure operational accuracy and stability. With intelligent design, whether it’s pallet-based, tote-based, or automated vertical storage systems, we deliver optimized solutions tailored to customer needs. These solutions not only maximize space utilization and reduce retrieval time, but also integrate seamlessly with modern software systems, enabling full-scale intelligent management.

Tailift’s pallet-based storage system is specifically designed to meet the warehousing and transportation needs of high-volume, heavy-duty products. Our system offers efficient inventory management, significantly improves space utilization, and simplifies operational procedures. With precise automation technology, our system enables fast and secure movement and retrieval of pallets, making it adaptable to a wide range of storage requirements.

Efficient pallet handling: Supports storage of heavy and large-volume items.

Maximized space utilization: Compact design allows for more items to be stored in limited areas.

User-friendly operation: Automation simplifies processes and enhances work efficiency.

Our tote-based storage system is designed for the storage needs of small to medium-sized items, ideal for applications requiring high flexibility and precision. This system is especially suitable for multi-variety, low-volume products, offering exceptional picking speed and accuracy. Powered by advanced automation technology, our system enables fast item retrieval to support diverse storage management needs.

Flexible storage solution: Ideal for storing a wide range of small to medium items in low quantities.

High-precision access: Automated systems enhance both speed and accuracy of retrieval.

Time and space-saving: Compact design ensures fast access and improved operational efficiency.

Tailift’s automated vertical storage system is the ideal solution for maximizing storage efficiency in limited spaces. By utilizing vertical space, the system significantly increases storage capacity and reduces retrieval times. Integrated with intelligent management software, this vertical storage solution seamlessly connects with existing logistics systems, enabling fully automated operations to boost warehouse efficiency and accuracy.

Maximum space utilization: Makes full use of vertical space to meet compact storage needs.

Fast retrieval: Greatly reduces picking time and enhances operational efficiency.

Smart management: Seamlessly integrates with existing warehouse software for complete automation.

Workflow

Tailift’s workflow is designed to ensure high quality and customer satisfaction. We begin with an in-depth analysis of customer needs to ensure a thorough understanding of every detail. Based on the results of this analysis, we develop the most suitable solution tailored to the customer’s business model and create a clear implementation roadmap. During the implementation phase, our professional team handles the equipment installation, ensuring all systems meet the highest quality standards. Finally, we conduct multi-level testing to guarantee the system’s stability and performance in real-world operations. Every step is carried out under strict management and monitoring to ensure flawless execution.

FAQ

Which industries are Tailift's storage solutions suitable for?

How do I choose the right storage system based on my needs?

Are Tailift’s automation systems scalable?

How long does the installation process take?

Does system maintenance require professional personnel?

why choose us

download brochure

Please download our document to see specific data of the aservice and how we work.