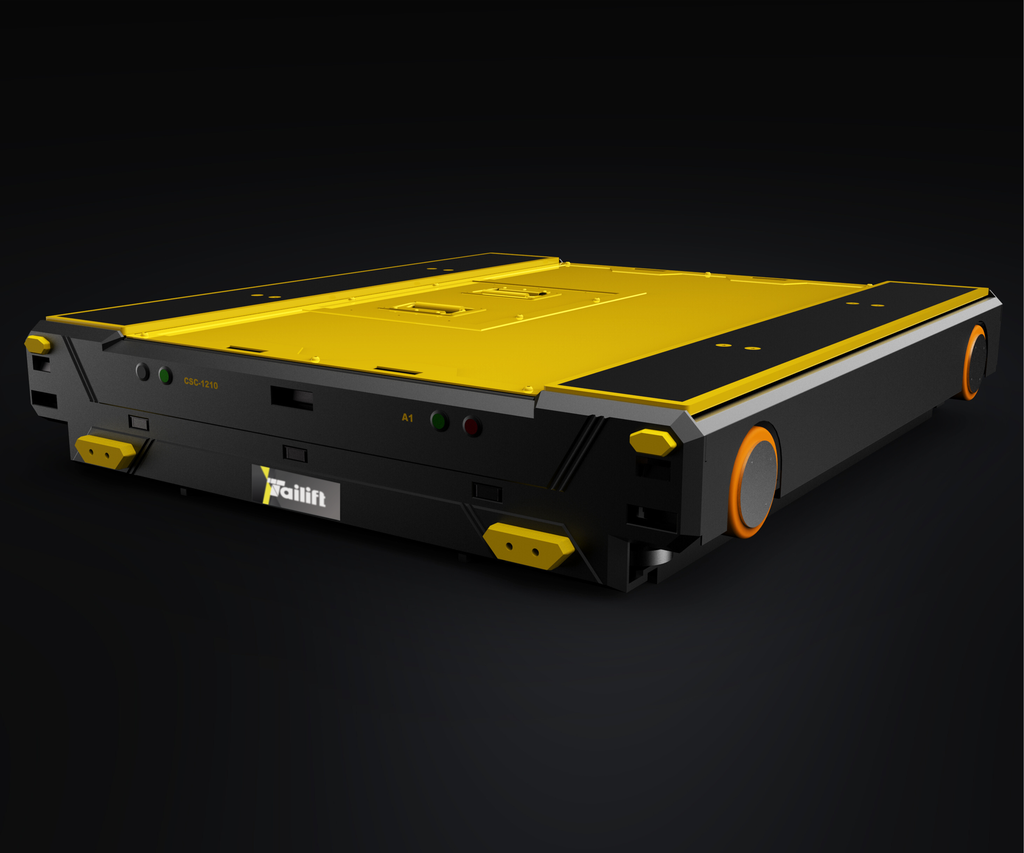

Bidirectional Shuttle Racking System

The bidirectional shuttle system uses a shuttle vehicle to semi-automate the transportation of goods within the rack tracks, reducing collisions between the stacker and the racks. Compared to traditional drive-in systems, it greatly increases the rack density, avoiding the risks of rack collapse due to human error and reducing maintenance costs, while improving inefficient access modes.

Features

-

Enhances operational safety by reducing collisions between racks and stackers, preventing rack collapse.

-

Reduces the aisle space needed for stackers, achieving high storage density and high space utilization.

-

High inbound and outbound efficiency, requiring operations only at the access points, increasing work efficiency.

-

Flexible storage methods, allowing for design planning in a first-in, first-out or first-in, last-out mode.

-

Suitable for industries with large quantities and high turnover of a small variety of goods.