Digital Intelligent Warehouse Operation System (WMS + WCS)

Take full control of warehouse logistics operations and build a high-efficiency intelligent warehouse.

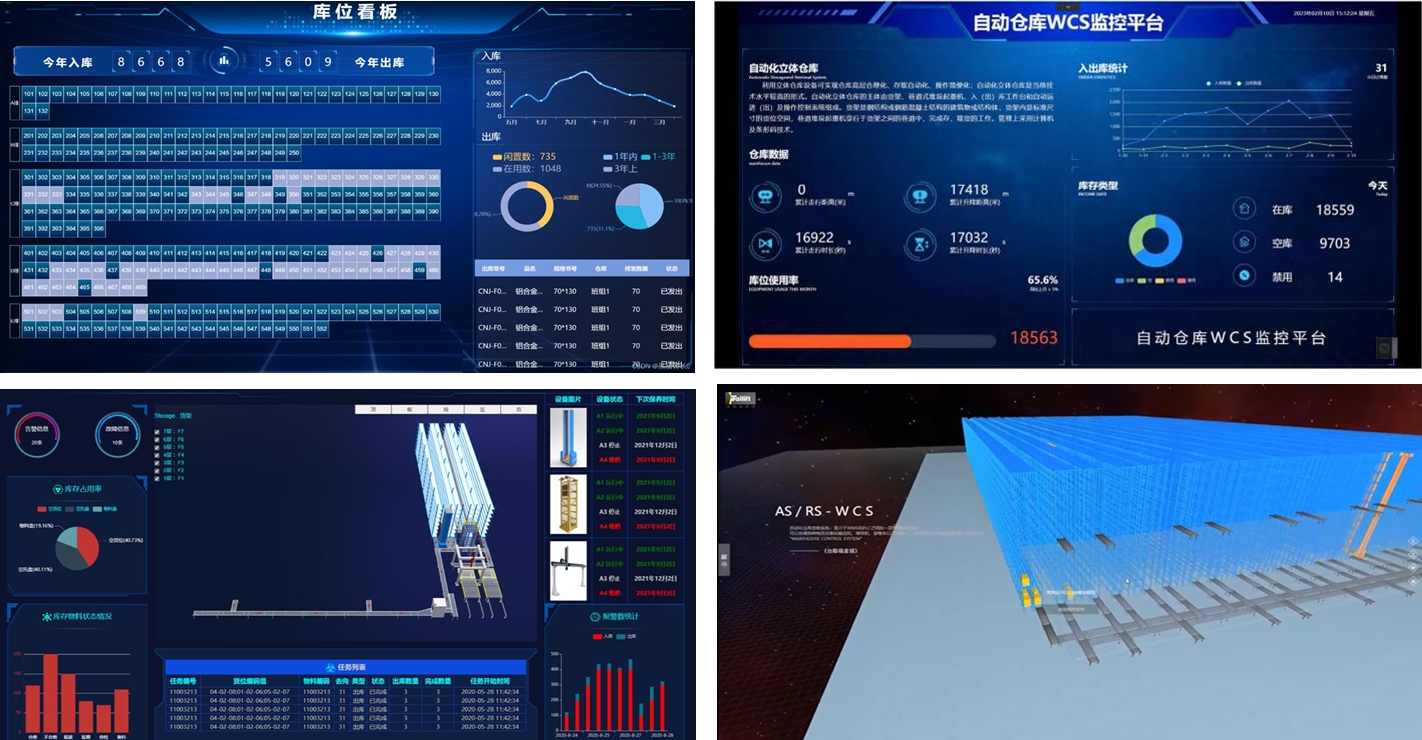

WMS (Warehouse Management System) is responsible for managing warehouse operation processes, including inbound, outbound, inventory, order management, and quality traceability. It ensures smooth material flow while reducing errors and losses.

WCS (Warehouse Control System) is responsible for intelligent dispatching of warehouse equipment such as stacker cranes, AGVs, AMRs, and conveyors, ensuring smooth and efficient logistics operations.

WMS – Warehouse Management

WCS – Warehouse Control

-

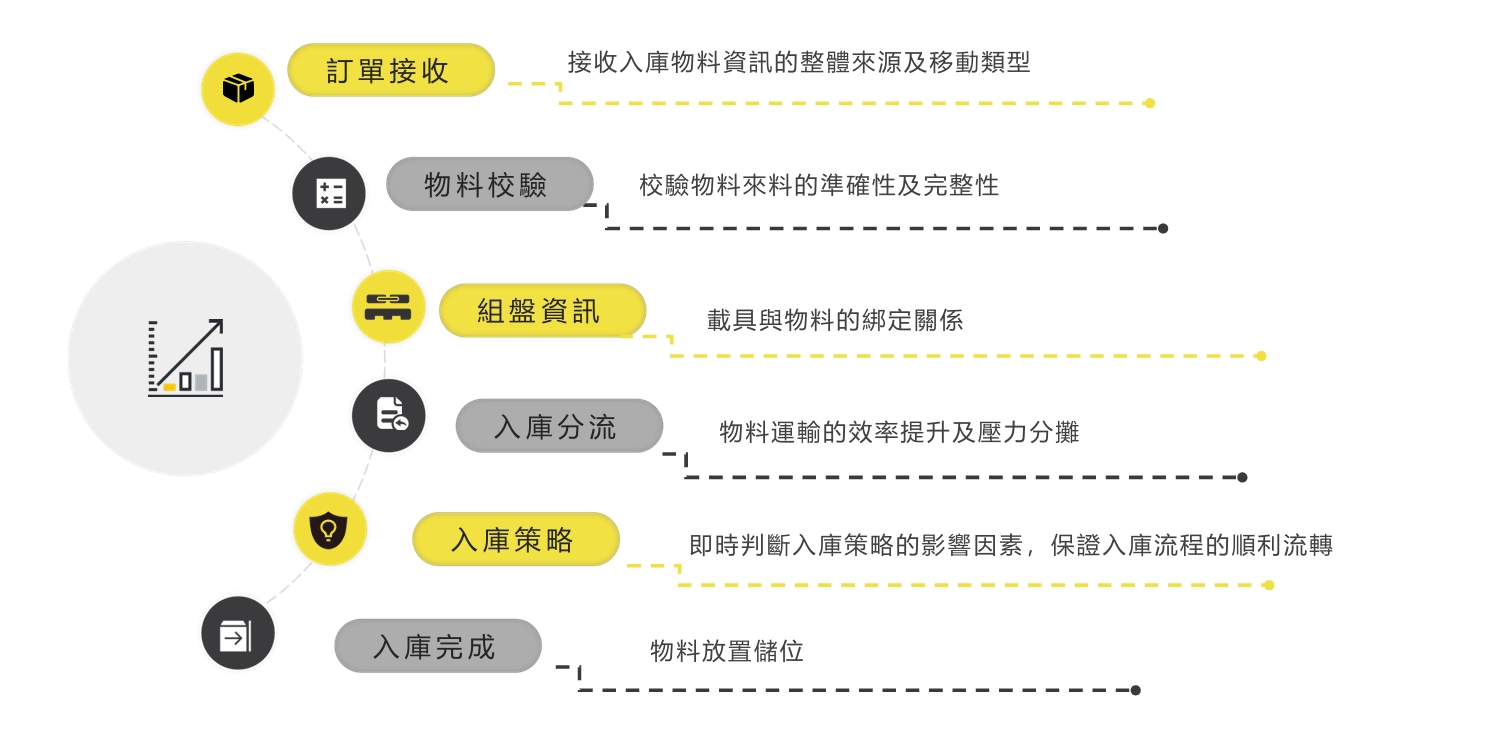

- WMS – 入庫功能

-

- WCS – 出庫功能

BI & Data Analytics

Big Data Drives Smart Decisions and Improves Warehouse Efficiency

TaiLift’s BI system combines data analytics and AI-powered computing to monitor inventory and logistics efficiency in real time, providing optimal decision-making support.

Core Functions

Solutions & Advantages | Innovative Technologies Empower Smart Logistics

In today’s rapidly changing market, businesses face growing demands in warehouse and logistics management. Traditional operational models can no longer keep up with increasing order volumes, complex supply chain processes, and the need for efficient deliveries. To help businesses enhance warehouse management, reduce operating costs, and optimize logistics, TaiLift introduces Smart Warehouse Solutions. Through digitization, intelligent systems, and automation, we enable end-to-end management—from receiving, storage, picking to distribution.

TaiLift’s Smart Warehouse Solutions cover three core areas: end-to-end intelligent warehousing, efficient logistics scheduling and equipment collaboration, and intelligent data analysis with decision-making support. These solutions significantly improve warehouse utilization, reduce labor dependency, and increase delivery accuracy. They are applicable to various industries such as e-commerce, manufacturing, cold chain logistics, and retail supply chains, helping businesses build efficient, flexible, and sustainable smart warehousing systems.

Digitize, automate, and optimize warehouse operations to increase efficiency and reduce costs.

TaiLift’s end-to-end intelligent warehousing solution leverages advanced automation and intelligent technologies to create a high-efficiency, low-cost, and error-free warehouse environment. Whether it’s storing components for large-scale manufacturing or rapid order fulfillment for e-commerce, this solution enhances warehouse management capabilities and ensures a stable, efficient supply chain.

AS/RS Automated Storage & Retrieval System

High-density storage and retrieval boosts warehouse space utilization and lowers space cost

Supports racking/box/pallet storage, suitable for managing various items

Intelligent Warehouse Management System (WMS)

Automated inbound and outbound processes reduce manual errors

Real-time inventory monitoring enables optimal storage allocation and fast picking

Unmanned Transport Systems (AGV / AMR / Shuttle)

Unmanned equipment improves internal logistics efficiency and reduces manual handling costs

Shuttles, stacker cranes, and RGVs support various operating modes

Applicable Scenarios: Large-scale manufacturing, e-commerce warehouses, pharmaceutical/cold chain logistics, retail supply chains

Smart dispatching + collaborative automation improves logistics speed and accuracy.

In warehouse operations, logistics scheduling and equipment efficiency directly impact the supply chain. TaiLift’s solution combines WCS and high-performance transport equipment to streamline material flow, fully integrate warehouse and logistics management, reduce transport time, and improve overall productivity.

WCS Smart Warehouse Control System

Integrates storage, transport, picking, and dispatch for coordinated workflows

Monitors logistics in real-time and dynamically adjusts delivery strategies

Logistics Robots (AMR, stacker cranes)

AMRs intelligently select optimal routes, reducing manual intervention

Stacker cranes and shuttles offer fast access, increasing throughput

Automated Sorting & Conveyor Systems

AI-powered sorting increases order accuracy and processing speed

Smart conveyors with robotic arms enhance automation level

Applicable Scenarios: E-commerce logistics hubs, FMCG distribution, internal smart factory logistics

AI and big data for optimized decision-making and smarter warehouse management

As logistics and warehouse scale grows, businesses require more accurate data for smarter decisions. TaiLift’s solution provides real-time visibility and analytics to reduce inventory surplus, improve order accuracy, and optimize supply chain performance.

BI Data Analytics Platform

Real-time dashboard visualizes inventory and goods movement

Demand forecasting refines replenishment strategy and minimizes excess stock

Smart Monitoring & Alerts

IoT devices track inventory temperature, humidity, and equipment status

Instant alerts notify managers of anomalies for timely response

Predictive Analysis & Supply Chain Optimization

AI predicts inventory needs, helping with advanced planning and space allocation

Optimization modules adjust logistics routes for the fastest delivery

Applicable Scenarios: High-tech supply chains, pharma & fresh storage, global trade logistics

FAQ

Q1: How does this intelligent warehouse system help improve our operational efficiency?

✔ Automated inbound and outbound operations reduce manual labor time and improve access efficiency

✔ Smart picking and sorting with AI-optimized routing increase picking accuracy up to 99%

✔ Integrated logistics robots (AGV/AMR) and shuttle systems reduce manual handling and error rates

✔ Real-time data monitoring reduces inventory overstock and optimizes storage space utilization

Q2: Is the implementation cost of the intelligent warehouse system high? What is the payback period?

✔ Minimizes errors and returns (warehouse accuracy improves to 99%)

✔ Improves space utilization (automated storage increases density by 30%)

✔ Enhances logistics speed (automated dispatch is 3x faster)

📌 We offer modular solutions tailored to your budget and needs, ensuring optimal ROI (Return on Investment).

Q3: Our current warehouse system is already in operation. Will the new system affect existing workflows?

✔ Modular deployment allows gradual expansion—no need for full replacement at once

✔ Supports both cloud and on-premise architecture for stable and highly available data

📌 Our expert team will evaluate your needs, ensure a smooth implementation, and provide full training to minimize transition costs

Q4: Can this system be used for multiple warehouses or overseas sites?

✔ Smart dispatching for optimal delivery, reducing inter-warehouse transport costs

✔ Cloud-based data storage ensures global access from any location

✔ Multi-language interface support for various regional markets

📌 Whether your warehouses are local, overseas, or spread across multiple locations, TaiLift’s intelligent warehouse solution enhances global supply chain management.

If the system encounters an issue, is maintenance and technical support available in real time?

We offer 24/7 technical support to ensure system stability.

✔ Remote monitoring and fault prediction detect issues early and reduce downtime risks

✔ Automated alerts immediately notify managers to resolve problems quickly

✔ Local and remote technical support ensures timely maintenance and upgrades

📌 Our system is highly stable with redundant backup, ensuring uninterrupted warehouse and logistics operations for seamless business continuity.

why choose us

download brochure

Please download our document to see specific data of the aservice and how we work.